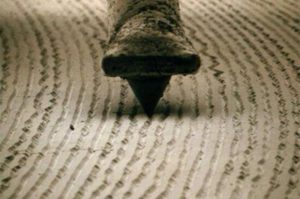

HDD Reading heads and vinyl player head. Cool comparison of how technology evolved. One picture shows a#vinylplate reading #needle that reads info (audio track) off vinyl plate, This one is actually touching surface and amplifies and then transforms needle vibrations in to a sounds and another one is a modern hard disk drive#magnetichead that flies above surface without touching it, reading data through changes in magnetic field surrounding magnetically charged particles (domens) in platter material. Here is what wikipedia says:

“HDD records data by magnetizing a thin film of ferromagnetic material on a disk. Sequential changes in the direction of magnetization represent binary data bits. The data is read from the disk by detecting the transitions in magnetization. User data is encoded using an encoding scheme, such as run-length limited encoding, which determines how the data is represented by the magnetic transitions.

A typical HDD design consists of a #spindle that holds flat circular disks, also called #platters, which hold the recorded data. The platters are made from a non-magnetic material, usually aluminum alloy, glass, or ceramic, and are coated with a shallow layer of magnetic material typically 10–20 nm in depth, with an outer layer of carbon for protection. For reference, a standard piece of copy paper is 0.07–0.18 millimeters (70,000–180,000 nm).

Recording of single magnetizations of bits on a 200 MB HDD-platter (recording made visible using CMOS-MagView). – (a green pic – added by QUBEX)

The platters in contemporary HDDs are spun at speeds varying from 4,200 rpm in energy-efficient portable devices, to 15,000 rpm for high-performance servers. The first HDDs spun at 1,200 rpm and, for many years, 3,600 rpm was the norm. As of December 2013, the platters in most consumer-grade HDDs spin at either 5,400 rpm or 7,200 rpm.

#Information is written to and read from a platter as it rotates past devices called read-and-write heads that are positioned to operate very close to the magnetic surface, with their flying height often in the range of tens of nanometers. The read-and-write head is used to detect and modify the magnetization of the material passing immediately under it.

In modern drives, there is one head for each magnetic platter surface on the spindle, mounted on a common arm. An #actuator arm (or access arm) moves the heads on an arc (roughly radially) across the platters as they spin, allowing each head to access almost the entire surface of the platter as it spins. The arm is moved using a voice #coil actuator or in some older designs a stepper motor.

Early hard disk drives wrote data at some constant bits per second, resulting in all tracks having the same amount of data per track but modern drives (since the 1990s) use zone bit recording—increasing the write speed from inner to outer zone and thereby storing more data per track in the outer zones.

In modern drives, the small size of the magnetic regions creates the danger that their #magnetic state might be lost because of thermal effects, thermally induced magnetic instability which is commonly known as the “superparamagnetic limit”. To counter this, the platters are coated with two parallel magnetic layers, separated by a 3-atom layer of the non-magnetic element ruthenium, and the two layers are magnetized in opposite orientation, thus reinforcing each other. Another technology used to overcome thermal effects to allow greater recording densities is perpendicular recording, first shipped in 2005, and as of 2007 the#technology was used in many HDDs.

In 2004, a new concept was introduced to allow further increase of the data density in magnetic recording, using recording media consisting of coupled soft and hard magnetic layers. That so-called exchange spring media, also known as exchange coupled composite media, allows good writability due to the write-assist nature of the soft layer. However, the thermal stability is determined only by the hardest layer and not influenced by the soft layer. “